Powerful Centrifugal Pumps

High-Flow Pumps

Banjo Fluid Transfer Pumps are engineered for tough jobs and demanding environments – from truck-to-tank to chemical applications, even in extreme weather conditions.

With flow rates up to 720 gallons per minute and options like wet-seal technology for run-dry protection, our Centrifugal Pumps offer the performance and reliability you need to keep operations running smoothly.

Built with durable materials like polypropylene, cast iron, and stainless steel, these pumps are stress-tested in a variety of use cases, so you don’t need to worry about leaks.

Built to Perform

From high-flow liquid transfer to chemical handling, Banjo Pumps are engineered to deliver.

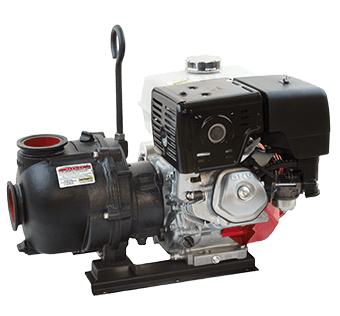

Introducing M350:

3" Transfer Pump Series

The M350 pump boosts spraying efficiency with FastFlow™ technology, delivering over 450 gallons per minute if fed with a 3” supply and up to 515 gallons per minute if fed with a 4” supply. Its patented tandem wet seal reduces wear and eliminates leaks, saving time and cost per acre. Ready-to-use and easy to retrofit, it minimizes downtime in the field.

Product Features

-

Lightweight & Corrosion-Resistant – Best for chemical and agricultural applications where durability and chemical compatibility are essential.

-

Precision-Molded Polypropylene Construction – Provides superior strength and resistance to aggressive liquids.

-

Seal Options – Available in EPDM, FKM, and BUNA-N (for certain models) to suit different chemical handling needs.

-

Temperature Rating – Handles from 0°F up to 150°F for various liquid transfer applications.

-

Available in Standard & Wet-Seal Models – Wet Seal versions protect seals with an ethylene glycol reservoir to help with run-dry situations.

-

Ideal for Loading Sprayers – Commonly used in fertilizer handling, irrigation, and chemical transfer applications.

-

Heavy-Duty & High-Pressure Performance – Designed for rugged agricultural and industrial environments.

-

Cast Iron Construction – Offers durability and extended longevity in demanding conditions.

-

Manifold Wet-Seal Technology (Select Models) – Prevents seal failure due to dry-run conditions.

-

Balanced Impeller Options (3" Models) – 333 Series includes dynamically balanced impellers for improved efficiency and longer lifespan.

-

Temperature Rating – Supports up to 300°F (149°C) depending on the seal material.

-

Best for Industrial & Agricultural Applications – Commonly used for wastewater systems, petroleum-based fluids, and high-pressure transfer.

-

Superior Chemical Resistance – Constructed from 316 stainless steel for extreme corrosion resistance.

-

Best for Highly Corrosive Applications – Handles acidic, caustic, and high-temperature liquids used in industrial processing, food-grade applications, and chemical transfer.

-

Temperature Rating – Supports up to 400°F (204°C) with appropriate seals.

-

Balanced Impellers (3" Models) – Increases pump efficiency and reduces mechanical wear.

-

Ideal for Extreme Chemical Handling – Used in chemical plants, industrial processing, and hazardous liquid transfers.

-

Enhanced Seal Protection – Features a double seal contained in an ethylene glycol reservoir to prevent damage when liquid flow is interrupted.

-

Available in Multiple Materials – Offered in polypropylene, cast iron, and stainless steel to suit different fluid transfer needs.

-

Designed to Help with Run-Dry Situations – Prevents seal failure and reduces maintenance downtime.

-

Temperature Ratings – 150°F (Poly), 300°F (Cast Iron), and 400°F (Stainless Steel) depending on seal material.

-

Common Uses – Ideal for sprayers, chemical transfer systems, and industrial operations requiring dry-run resistance.

-

Industry-Leading Flow Rates – Achieve over 500 gallons per minute with FastFlow™ technology, reducing downtime and operational costs.

-

Innovative Tandem Wet Seal Design – Minimizes wear, prevents seal breakage from high-pressure clean-outs, and eliminates eight potential leak points.

-

Durable Polypropylene Construction – Molded from glass-filled polypropylene with EPDM seals and stainless steel hardware for enhanced chemical resistance and longevity.

-

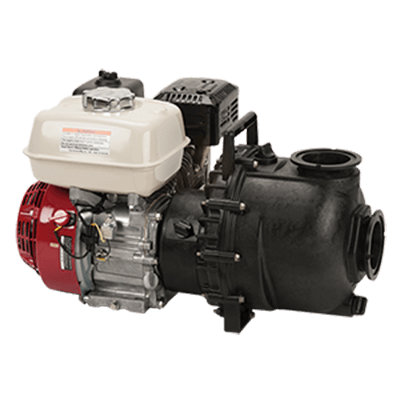

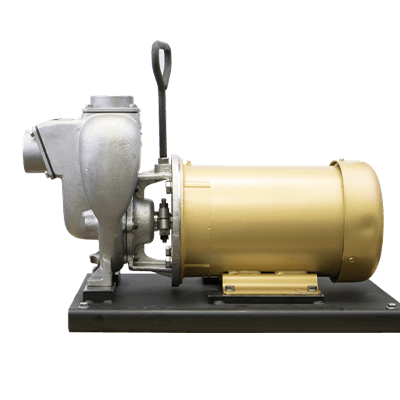

Versatile Power Options – Compatible with gas engines (e.g., 14 HP Vanguard), electric motors, hydraulic motors, and bearing pedestal configurations to suit various operational needs.

-

Self-Priming Capability – Maximum self-priming height of 28 feet for standard versions and 25 feet for hydraulic versions, ensuring efficient operation.

-

Solid Particle Handling – Capable of managing occasional solid particles up to ½ inch in diameter, making it suitable for diverse applications.

-

Run-Dry Resilience – Designed to withstand over one hour of dry running, reducing maintenance and downtime.

-

Seal Protection & Leak Prevention – Wet Seal Kits prevent seal damage during dry operation, while Mechanical Seal & O-Ring Kits help maintain leak-free performance.

-

Mounting & Stability – Bearing Pedestal Assemblies allow for custom motor setups, and Universal Baseplate Assemblies reduce vibration for longer pump life.

-

Power Integration Options – Choose from Hydraulic Motor Kits (Parker®) for precision flow control, Electric Motor Mounts (Baldor®, Marathon®) for seamless motor alignment, or Gas Engine Options (Honda®, Briggs & Stratton®) for portable power solutions.

-

Flow Efficiency & System Protection – Impeller & Wear Plate Kits restore optimal flow rates, Check Valves & Fittings prevent backflow, and Spool Valve Assemblies ensure smooth hydraulic pump operation.

-

Quick Installation & Adaptability – Manifold Flange Connection Kits eliminate threaded fittings for leak-free assembly, while Adapter Shafts & Couplings provide precise alignment between pumps and power sources.

Are you a distributor looking for detailed part info? Visit our distributor portal.

Why Choose Banjo Pumps?

Banjo’s Liquid Transfer Pumps give you peace of mind because they can stand up to the toughest conditions and applications.

High-Flow Capacity

Wet-Seal Technology

Durable Construction

Easy Maintenance

Flexible Power Configurations

Material Compatibility

Run-Dry Protection

USA-Made Quality

Customizable Solutions

Industry-Leading Support

Liquid Transfer You Can Depend On

When it comes to liquid handling, quality matters. That’s why Banjo Pumps combine smart design with robust materials. Each pump can handle aggressive fluids, high pressures, and heavy workloads with ease.

Upgrade Your Liquid Handling System Today

Discover what sets Banjo Pumps apart from others – designed with durable materials, advanced technology, and flow rates up to 720 GPM. Our network of experienced distributors is ready to help you find the perfect solution for your operation, wherever you are.